+44 (0)1142041541

info@ernestwright.co.uk

$ USD

-

£ GBP

-

$ USD

-

€ EUR

$179.68

Out of stock

Attention

This model is currently out of stock. It is not available on backorder, as we have not yet started the process of producing a batch of this particular model. As soon as we have a good estimate on the schedule for a new batch, we will switch the status of this model to "Back-order" or even to "In Stock".

The 10″ Sidebent Tailor Shears (or 10″ Dressmaker) is a high quality tool for professional use. Now, we offer this ‘classic’ not only in a regular, but also in a left-handed version, the 10″ left-handed tailor shears. An outstanding product, used by tailors over the world. It’s perfect to cut through most fabric, and is a real eye-catcher with its mirror polish finished, 5.18″ blades. As all our products, these shears are hand-made with professional quality. So you can cut with ease, optimizing your workflow.

Type: left-handed Tailor shears / Dressmaker shears

Use: Tailors and dressmakers, cutting fabric

Total length: 10″ / 25.4 cm

Blade length: 5.18″ / 13.20 cm

Weight: 365 g

Material: Drop forged high quality carbon steel,

long-life precision edge retention

Finish: Hand polished

Packaging: High Quality presentation box

There can be few working relationships closer than that between a tailor and their shears. Each day, the shears serve as an extension of the tailor’s arm and mind, making hundreds of millimetre-perfect cuts to create garments that fit the client’s measurements exactly. Whenever we talk to passionate tailors, we hear about this symbiosis between the craftsperson and the tool of their trade.

For left-handed tailors, finding the perfect shears can be relatively challenging. Professional tailor shears are a highly specialised product to begin with – and left-handed shears are even more so, as they require a design that’s mechanically opposite to the equivalent right-handed shears, in order to work correctly. For many scissors-makers, producing that special version of a special type of shears proves to be economically unviable, so left-handed tailors end up underserved.

This is why we’re especially proud to offer a pattern of 10″ Tailor Shears for left-handed users. The pattern offers exactly the same qualities as its right-handed counterpart. The only difference is that they work in the left hand, not the right.

A nice bonus, for left-handed tailors, is that you’re less likely to have colleagues borrow your shears (without asking!) for odd jobs around the workshop. A tailor and their shears should never be parted!

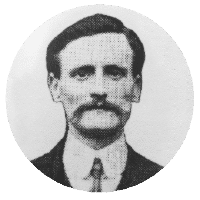

Ernest Wright

(1880-1954)