+44 (0)1142041541

info@ernestwright.co.uk

$ USD

-

£ GBP

-

$ USD

-

€ EUR

$179.54

Availability: In stock

Attention

This model is in stock and available directly from our workshop. We’ll prepare and dispatch it within 10 working days of your order.

The 10″ Sidebent Tailor Shears (or 10″ Dressmaker shears) is a high quality tool for professional use. An outstanding product, used by tailors over the world. It’s perfect to cut through most fabric, and is a real eye-catcher with its mirror polish finished, 5.18″ blades. As all our products, these shears are hand-made with professional quality. So you can cut with ease, optimizing your workflow.

Type: Tailor shears / Dressmaker shears

Use: Tailors and dressmakers, cutting fabric

Total length: 10″ / 25.4 cm

Blade length: 5.18″ / 13.20 cm

Weight: 364 g

Material: Drop forged high quality carbon steel,

long-life precision edge retention

Finish: Hand polished

Packaging: High Quality presentation box

More than just a term made up to describe a high level of polish, ‘mirror polishing’ is a specific process with clearly defined objectives. Not only does the mirror finish give the steel a reflective surface that’s free from visible irregularities or imperfections; it also makes the bows and shanks supremely smooth and comfortable to hold which is crucial for any professional expected to handle shears for multiple hours a day.

We mirror-polish scissors and shears such as our professional tailor shears through a set of special tools and techniques. The first key step is rumbling, during which the shears are cycled through a vibratory polishing machine known affectionately as ‘the rumbler’. This machine has a trough filled with porcelain beads and a polishing solution, both of which help to remove marks left over from intense processes such as bench-grinding and belt-sanding.

After rumbling comes a succession of finer polishing processes. Some of these involve special pieces of equipment, such as soft ‘scurf’ or ‘bob’ wheels loaded with polishing compound, which gently abrase the steel. A final cosmetic polish is done by hand, before the mirror-polished shears are sent out to scatter the glorious sunlight in your corner of the world.

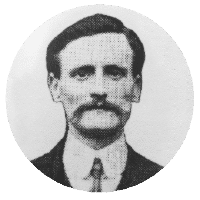

Ernest Wright

(1880-1954)