+44 (0)1142041541

info@ernestwright.co.uk

£ GBP

-

£ GBP

-

$ USD

-

€ EUR

£94.00

Availability: In stock

Attention

This model is in stock and available directly from our workshop. We’ll prepare and dispatch it within 10 working days of your order.

Like all Ernest Wright scissors and shears, the 8.25″ Dressmaker shears begin as two solid bars of carbon steel. Through the traditional process of hot forging, a bar is converted into a blank before our masterputtertogetherers get to work. The die for the 8.25″ is an old Sheffield pattern unearthed and revitalised. Made to order, these unique scissors will never let you down.

Type: Dressmaker scissors / Tailor shears

Use: Tailors and dressmakers, cutting fabric

Total length: 8.25″ / 21 cm

Blade length: 3.75″ / 9.5 cm

Weight: 180 g

Material: Drop forged high quality carbon steel,

for long-life precision edge retention

Finish: Hand polished

Packaging: High Quality presentation box

Note: we also have a left-handed version.

Sidebent shears, like the 8.25″ Sidebent Dressmaker, have shanks that project upwards and away from the blades. This means that the top bow and the bottom bow (the loops held by your thumb and fingers), are offset and respectively above and aligned with the blades. Hence, sidebent.

Tailors and dressmakers often need to make long cuts in fabric, while working on a tabletop. This gives us the reason to make scissors and shears with a sidebent design. If the craftsperson were using shears with straight shanks, then the bottom bow would catch against the edge of the table, making the shears much harder to use. With a sidebent design, the user can rest the shears flat against the tabletop, enabling smooth, efficient cutting.

Sidebent scissors designs were patented by a Sheffield scissors-maker, Thomas Wilkinson, in 1800. The inventor’s firm, Thomas Wilkinson & Sons, received First Class Prize Medals at the Great Exhibition of 1851 and the Paris Exhibition of 1855. Still to this day, busy tailors owe a debt of gratitude to Wilkinson’s clever sidebent design.

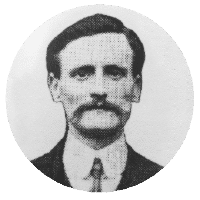

Ernest Wright

(1880-1954)