+44 (0)1142041541

info@ernestwright.co.uk

$ USD

-

£ GBP

-

$ USD

-

€ EUR

$268.94

Availability: Available on back-order

Attention

We are currently in the process of making a batch of this model, and some of the units being produced are still available to backorder. We expect the batch to be finished within 10 weeks, after which point the backorders can be fulfilled. This timescale should be taken as a conservative estimate, not a guarantee, as our production is limited and subject to change due to external factors.

The 12″ hardened industrial shears are designed for hard work. If you’re a craftsman who loves our scissors but worries that the other styles won’t quite cut it, then these are the shears for you. Handmade and expertly put together, they have the same precision and feel that make Ernest Wright scissors world-famous; but with 6″ hardened carbon steel blades, they cut with confidence through all types of technical textiles. Letting you focus on your craft.

Type: Cutting all kind of (technical) fabrics

Use: Tailors and craftsmen, cutting (technical) fabric

Total length: 13″ 1/4 / 33.02 cm

Blade length: 6,3″ / 16 cm

Weight: 830 g

Material: Drop forged high quality carbon steel,

long-life precision edge retention

Finish: Hand polished

Packaging: Leather holster

We need to use extremely durable steel to equip shears for the toughest cutting applications. This applies to all of our tailoring shears patterns – and especially the 12″ Industrial Shears, a durable, long-lasting pattern intended for cutting upholstery and technical fabrics.

There are a few different ways to test the hardness of steel. We tend to use the Rockwell hardness testing method. The shears forging is secured on a Rockwell hardness testing device, then indented twice using a diamond indenter, under a different load each time. The difference between measurements for the two loads gives us a read on the hardness of the steel. If the shears forging is as hard as expected, we’ll know that it can be used to make a suitably durable pair of shears.

Another key testing process is using the finished shears to cut relevant sample materials. Sometimes, the customer will send us a sample of fabric – such as tough denim, neoprene or a rigid plastic – so that we can try cutting it with the shears, before confirming the order.

We hear some amazing tales about the capabilities of the 12″ Industrial Shears. As a model that would historically have been more commonplace as a pair of upholstery shears, the 21st century sees this model being used to cut Kevlar, a technical fabric used to make bulletproof vests.

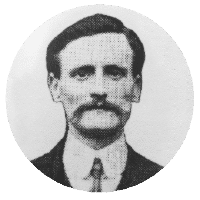

Ernest Wright

(1880-1954)