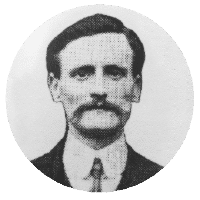

We recently received a wonderful email from Mrs Ann Palmer, whose grandfather, W. H. Bolton, contributed greatly to the Sheffield scissors trade in the 20th Century. Mrs Palmer’s letter details how Mr Bolton invented a method for setting scissors blades in such a way that their edge retention is improved. Here we reproduce the letter, plus some fascinating photographs, in full.

Dear Team Ernest Wright,

Having read with interest your Christmas Newsletter, which was forwarded to me by a friend, I am inspired to write to you with a snippet of Sheffield history. The name “Ernest Wright” was immediately familiar to me from the lips of my grandfather – W. H. Bolton (Harry) – who was an instigator, and prime mover, of the Sheffield Trades Technical Society (later the National T.T.S.) from its inception in 1918 until his retirement in 1962, at the age of 78! The aim of the Society, which operated under the aegis of the University, was to provide a wider technical education to workers in the steel industries – more particularly the cutlery and scissor-making trades – before the existence of evening classes. Courses were held, at the University, in metallurgy and technical science with the aim of improving the skill and understanding of the (mostly) men who were “hands on” in the various techniques of production.

My grandfather, who had been trained as an engineer in the early years of the 20th century, worked for the firm of Hattersley & Davidson, rising to the position of works manager, before leaving, in 1918 to become the first secretary of the newly formed Sheffield Trades Technical Society. His abiding interest in scissor manufacture led him to invent a new method of setting the two scissor blades in order to eliminate the friction which, over time, caused the blades to lose their edge. One or two pairs of the new scissors were made by a friend in the trade and my grandfather had a pair sent to Cole Brothers department store in Fargate for a trial period of six months, following which he received this letter, dated 6th March 1922:

W. H. Bolton,

Dear Sir,

I have thoroughly tested the scissors having had them in constant use, since last September & have found them most satisfactory in every way, the screw remaining absolutely firm & the edges perfect.

Yours faithfully, N. Pike

(Mantle Cutter).

I have also attached a copy of a hand-written note, signed: F. Knight, referring to the manufacture of the scissors which will mean much more to you than to me! The scissors never got into general production, however – they were not felt to be “economical”. As nowadays built-in obsolescence had more appeal for the mass-marketeers! Discouraged, my grandfather abandoned inventing and gave his energy to developing the Technical Society!

On his retirement, in 1962, the University awarded him the honorary degree of Master of Technical Science – possibly by coincidence – it was at the same degree ceremony that I received my BA Honours degree! I enclose the photograph, taken in the quadrangle at Western Bank, with my parents, both of whom also graduated from the University, back in 1938.

As part of my 21st birthday present (cutlery & scissors, what else?) my grandfather gave me a set of three pairs of scissors, for sewing, in a leather case. Sixty years later I am still using them. The mark is “Ragg, Sheffield”. I know nothing of the makers, although Wragg, with a W, is a distinctly local surname. Unfortunately the middle one of the three pairs was damaged, some years ago, in that one of the blades is slightly distorted so that the scissors no longer cut properly. Could they be reset – if I can get them to you? I live in Brittany and am not inclined to put them in the post due to the problems with Customs, since Brexit. I visit Cornwall, where my daughter lives, once or twice a year, and could post them from there. Perhaps you would be kind enough to let me know.

With kind regards and looking forward to further instalments of the newsletter,

Ann Palmer (Mrs)