+44 (0)1142041541

info@ernestwright.co.uk

$ USD

-

£ GBP

-

$ USD

-

€ EUR

$120.39

Availability: In stock

Attention

This model is in stock and available directly from our workshop. We’ll prepare and dispatch it within 10 working days of your order.

The 8.25″ Left-handed dressmaker shears are of high quality and easy to use. We make a right-handed version and a left-handed version. A versatile scissor, they are perfect for cutting through textiles and tough fabric (canvas, rope, carpet, rubber), making them fit for both professional and daily tasks. Lightweight and capable, the 3.75″ carbon steel blades will never let you down. Hot forged and hand made in Sheffield, by craftsmen with traditional techniques. A mirror finish makes these shears the most beautiful tool you’ve ever owned.

Type: Dressmaker shears / Tailor shears – Left-handed

Use: Tailors and dressmakers, cutting fabric

Total length: 8.25″ / 21 cm

Blade length: 3.75″ / 9.5 cm

Weight: 180 g

Material: Drop forged high quality carbon steel,

for long-life precision edge retention

Finish: Hand polished

Packaging: High Quality presentation box

Cast your mind back to your school days, and you may recall wondering why, as a left-hander, you couldn’t use the same scissors as most of the other kids. The scissors all looked the same – so what was the difference?

When you use a pair of scissors or shears, your hand should squeeze the blades together, at the same time as closing them vertically. This lateral squeeze (which the hand applies naturally) means the edges of the blades are pressed together closely, enabling their ‘bypass’ cutting action. So, when a right-handed pair of scissors is used in a left hand, the hand will tend to squeeze the blades away from one another, resulting in a wide, messy cut.

Left-handed scissors and shears are made as mechanical mirror images of their right-handed counterparts, so that the blades can be pushed together by the user’s hand in a natural cutting motion. Some left-handed folk have some success in making right-handed scissors or shears work in their hand, by cleverly adjusting their technique. However, the smarter long-term solution for comfortable, accurate cutting is to choose a pattern of scissors or shears that’s made for left-handed use.

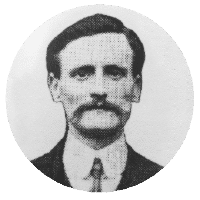

Ernest Wright

(1880-1954)